WEEDSWIPER

Precision Weed Control for UK Farmers

Looking for a smarter way to control weeds without wasting chemicals? The weed wiper from Fentech Agri delivers targeted herbicide application that protects your crops whilst slashing costs. Unlike traditional farm weed sprayers that blanket entire fields, this innovative weed wiper for tractor and ATV use applies herbicide only where it’s needed. Consequently, you eliminate chemical drift and dripping, making it perfect for use near waterways, conservation areas, and sensitive crops.

Furthermore, the weed wiper combines intelligent sensor technology with a proven non-drip pad system. As a result, you’ll cut herbicide costs dramatically whilst supporting sustainable weed management that preserves biodiversity across your land.

Efficiently applies herbicide only to target plants, reducing waste and preventing chemical drift in sensitive areas.

Operates effectively in windy or restricted environments like wetlands and conservation areas where spraying is not feasible.

Electronic hydrostat controller maintains ideal pad moisture, ensuring consistent chemical transfer for maximum weed control.

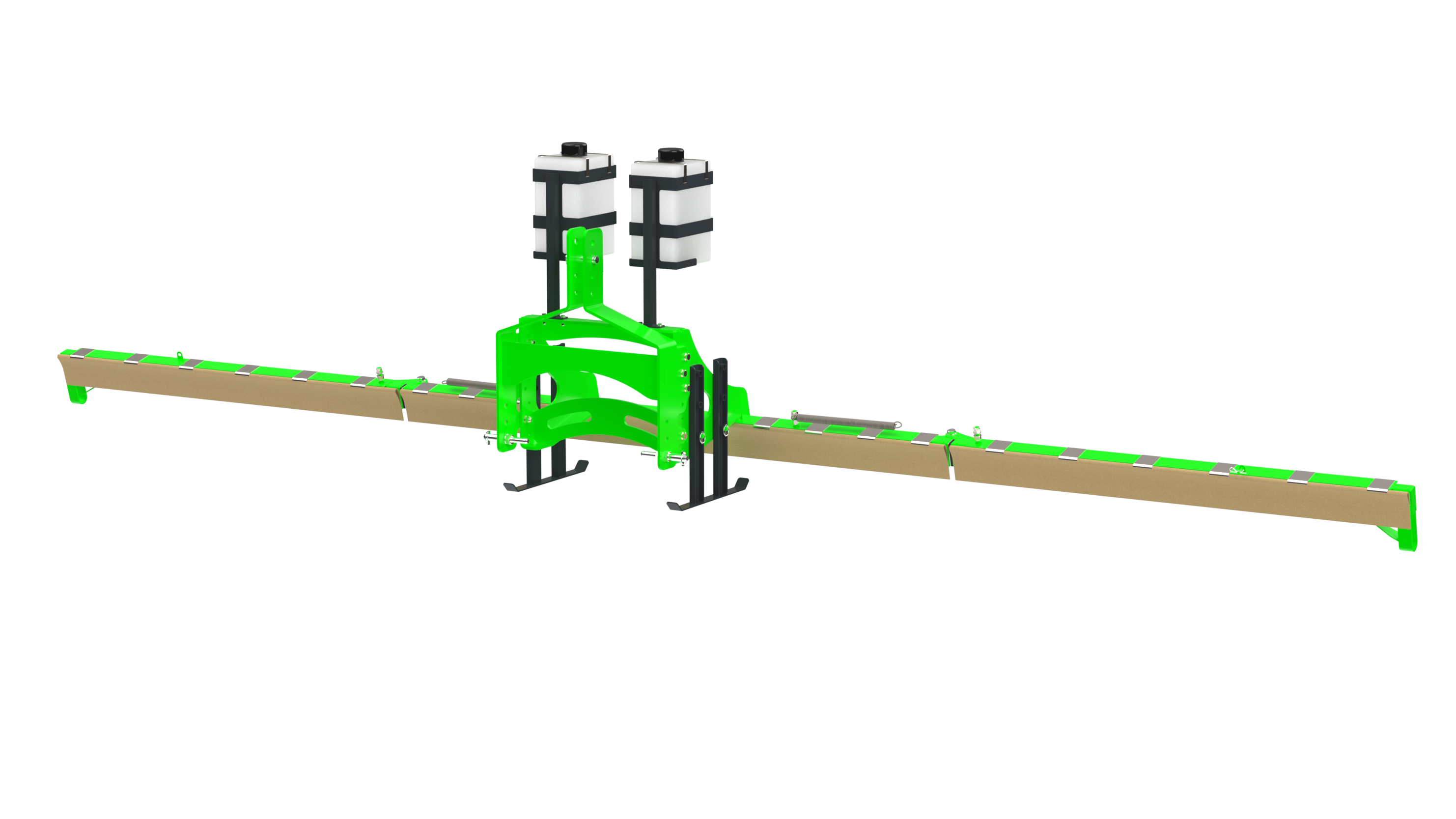

Foldable boom sections with 3-point linkage enable convenient road transport and versatility across different fields.

Transform Your Weed Management Strategy

The Fentech Agri Weedswiper represents a breakthrough in selective weed control for UK farmers seeking cost-effective, sustainable solutions. Specifically, this innovative herbicide applicator delivers targeted weed killer directly to problem plants while protecting valuable crops underneath. Unlike traditional farm weed sprayers, this advanced weed wiper for tractor and ATV use eliminates chemical drift and dripping. As a result, it proves ideal for sensitive environments including grassland, conservation areas, and waterways.

Designed specifically for small to medium-sized farming operations, the Weedswiper combines intelligent sensor technology with a proven non-drip pad system. Consequently, this approach cuts herbicide costs dramatically whilst supporting sustainable weed management practices. Furthermore, it helps preserve biodiversity and reduce environmental impact across your land.

What Is a Weed Wiper and How Does It Function?

A weed wiper applies herbicide through direct contact rather than spraying. Essentially, the system uses herbicide-moistened pads that brush against taller weeds, taking advantage of the height difference between target plants and the crop below. As a result, this contact-based method ensures precise application without the wastage and drift associated with conventional spraying.

The Weedswiper takes this proven concept further with advanced electronic controls. In practice, built-in sensors monitor pad moisture levels continuously, switching the pump on and off to maintain the right amount of herbicide transfer. Therefore, the pads remain wet enough for effective weed control but never become too wet to cause dripping. Moreover, this intelligent regulation works regardless of travel speed or weed density, delivering consistent results across varying conditions.

How Do Weed Wipers Work for Selective Weed Control?

Selective weed control targets specific problem plants whilst leaving desirable vegetation unharmed. Importantly, the Weedswiper excels at this precision approach through several key mechanisms.

The 150mm deep pads create a reservoir of active ingredient with excellent fluid retention properties. When taller weeds make contact with these tufted pads, they receive a sufficient dose of herbicide whilst shorter crops below remain untouched. Consequently, this height-selective application proves particularly valuable for weed management in wheat, maize, and grassland where crop protection is essential.

Furthermore, the electronic control system ensures each target weed receives consistent herbicide coverage. Unlike basic wiping tools where pad wetness varies with use, the Weedswiper maintains the right moisture level throughout operation. As a result, this reliability translates to better weed kill rates and fewer repeat applications.

Cost Savings That Make Sense

Small and medium farmers face constant pressure to reduce input costs whilst maintaining productivity. The Weedswiper delivers measurable savings across multiple areas:

Herbicide expenses drop significantly because you apply chemicals only to weeds rather than entire fields. For a typical grassland operation, this targeted approach can reduce annual weed killer costs by hundreds of pounds per hectare.

The lightweight construction and simple mounting system mean lower fuel consumption compared to pulling heavy spray equipment. Fast setup times reduce labour costs – you can hitch up and start work in minutes rather than the lengthy preparation conventional sprayers require.

A hire option available through Fentech Agri allows farmers to access the technology without major capital outlay. Contact the team for rental details and seasonal availability. This flexibility helps manage cash flow whilst still achieving excellent weed control results.

Technical Specifications and Working Widths

The Weedswiper runs from a standard 12-volt vehicle battery, making it compatible with most tractors. Additionally, three-point linkage mounting (CAT1/2) ensures secure attachment and easy transport between fields.

Furthermore, the foldable boom design incorporates a simple end break-back return system. This safety feature protects the equipment when obstacles are encountered, whilst the compact folded width makes road transport straightforward.

For smaller operations, the trailed kit converts the weed wiper for quad bike or UTV use in minutes. As a result, this versatility means the same unit serves multiple purposes across your farming enterprise.

Advantages of Using a Weed Wiper Over Traditional Spraying

Traditional farm weed sprayers face significant limitations that the Weedswiper overcomes:

Weather-Resilient Operation: Conventional spraying requires calm conditions to prevent drift. The Weedswiper works effectively even in wind, expanding your application window considerably. This weather independence proves invaluable during busy farming periods when waiting for perfect conditions isn’t practical.

Reduced Chemical Use: Broadcast spraying applies herbicide across entire fields, including weed-free areas. The targeted application of this weed wiper for sale applies chemicals only where weeds make contact, cutting herbicide costs by up to 70% compared to traditional methods.

Environmental Protection: The non-drip design prevents herbicide from reaching soil, water, or desirable plants. This makes the system suitable for use near waterways, in conservation areas, and on organic farms where chemical minimisation is essential for sustainable weed control.

Crop Safety: Dripping and drift from sprayers can damage susceptible crops. The Weedswiper’s controlled contact application eliminates these risks entirely, protecting crop yield and quality.

Fast Setup and Easy Transport Between Fields

Productivity matters on busy farms. Therefore, the Weedswiper’s design prioritises quick deployment and efficient field-to-field movement.

The foldable boom system allows single-operator setup in under five minutes. Simply hitch to three-point linkage, connect the 12-volt power supply, fill the herbicide tank, and you’re ready to work. Importantly, no complex calibration or lengthy preparation slows you down.

When moving between fields, fold the booms to their compact width for safe road transport. Additionally, the lightweight construction means minimal impact on tractor fuel consumption compared to pulling heavy conventional sprayers.

The trailed kit option adds further versatility. For instance, you can convert from tractor mounting to ATV or UTV compatibility quickly, allowing the same unit to serve multiple roles across your enterprise. As a result, this flexibility maximises equipment utilisation and improves return on investment.

Weather and Terrain Adaptability

UK farming means working in challenging conditions. The Weedswiper handles situations where conventional spraying simply isn’t feasible:

Windy Conditions: Spray drift becomes unacceptable in even moderate wind. The contact-based application works reliably regardless of wind speed, keeping operations running when sprayers must stay in the shed.

Wetland and Marshland: Sensitive environments require extra care. The non-drip system prevents herbicide reaching water whilst still controlling invasive species. Conservation managers and environmental stewardship participants particularly value this capability.

Sloping Ground: Pad height adjusts easily to suit different terrains. Whether working rolling hillsides or flat fields, maintain consistent weed contact for reliable control.

Variable Weed Heights: The adjustable system accommodates different target heights within the same pass. Set the pads to contact the tallest problem weeds whilst clearing shorter crops comfortably underneath.

Weed Management in Specific Crops

Different crops present unique weed management challenges where the Weedswiper excels:

Weed Management in Wheat: Grass weeds like black-grass often grow taller than wheat crops, making them ideal targets for wiper application. The system applies herbicide to these problem grasses whilst leaving the wheat completely unharmed.

Weed Management in Maize: During early growth stages, maize plants remain shorter than many broadleaf weeds. The height-selective application controls these weeds effectively without crop contact, supporting clean establishment.

Weed Management in Natural Farming: Systems emphasising minimal intervention benefit from the precise, low-volume application. The targeted approach controls problem species whilst allowing beneficial plant diversity to flourish.

Grassland Applications: Docks, thistles, and nettles commonly plague productive grassland. The Weedswiper tackles these taller weeds effectively whilst preserving valuable grass species, improving pasture quality without reseeding.

Engineered for Consistent, Controlled Results

Reliability defines successful farming equipment. Therefore, the Weedswiper’s engineering delivers predictable performance through proven components:

The electronic pump control responds instantly to pad moisture changes, maintaining the right amount of herbicide transfer continuously. As a result, this automatic regulation eliminates the guesswork and manual adjustment that plague simpler systems.

Furthermore, premium pad materials provide excellent fluid retention whilst ensuring effective herbicide transfer on contact. The 150mm depth creates substantial active ingredient reserves, maintaining consistent application rates throughout extended work periods.

Additionally, robust construction handles the rigours of daily farm use. The simple boom break-back system protects against damage when obstacles appear, whilst quality components ensure season after season of dependable service.

Target Weed Killer: Precision That Preserves Biodiversity

Modern farming increasingly balances productivity with environmental responsibility. Importantly, the Weedswiper supports this dual objective through genuinely targeted herbicide application.

By applying chemicals only where weeds make direct pad contact, the system preserves beneficial plant diversity throughout fields. Consequently, field margins, wildflower strips, and hedgerow bases remain uncontaminated, supporting pollinator populations and natural pest predators.

Furthermore, this precision approach allows farmers to meet environmental stewardship requirements whilst maintaining productive land. In practice, you control problem species effectively without the blanket chemical coverage that harms beneficial ecosystems.

Additionally, the reduced drift and runoff risk means safer operation near sensitive areas. Therefore, you can work confidently alongside waterways, organic neighbours, or conservation zones knowing the non-drip design prevents contamination.

Optimal Saturation: The Technology Behind Consistent Performance

The secret to effective wiper performance lies in maintaining ideal pad moisture levels. Too dry, and weed kill rates suffer. Conversely, too wet, and dripping wastes herbicide whilst potentially damaging crops below.

Fortunately, the Weedswiper’s sensor technology solves this challenge automatically. By monitoring pad saturation constantly, the system activates the pump precisely when additional herbicide is needed. As a result, this continuous regulation maintains the right balance between inadequate coverage and wasteful over-saturation.

Moreover, this intelligent control works across varying conditions. Whether you’re moving quickly through light weed pressure or working slowly through heavy infestation, the pads remain at the right moisture level. Therefore, travel speed and weed density no longer affect application quality – the electronics handle the adjustments automatically.

Best Practices for Maintaining a Weed Wiping Tool

Proper maintenance ensures consistent performance and long service life. Therefore, follow these straightforward guidelines:

After Each Use: Thoroughly clean all components with the included clean water wash tank. This quick rinse prevents herbicide build-up and keeps the pump and lines flowing freely. Importantly, the simple cleanup takes just minutes but prevents costly blockages.

Pad Care: Inspect pads regularly for wear or damage. The tufted material proves remarkably durable, however it eventually requires replacement after extended use. Additionally, store units with the supplied pad covers fitted to prevent accidental contamination and protect pad integrity.

System Checks: Verify sensor function before each season. The electronic controls should activate the pump smoothly when pad moisture drops. Furthermore, check all electrical connections for corrosion, particularly if storing equipment outdoors.

Winter Storage: Drain all herbicide from tanks and lines before long-term storage. Next, run clean water through the complete system, then store in a dry location with pad covers fitted. As a result, this simple routine ensures reliable spring startup.

TECHNICAL SPECIFICATIONS:

ApplicationS:

- Grassland

- Arable

- Wetland

- Conservation Areas

- Bracken

FEATURES:

- 6m working width

- Sprung loaded boom

- Hardwearing, tear resistant fabric used for the pads

- 3 point linkage mounting

- Folds to 2.6m for road transport

- Hydrostat control system – keeps the pads at the correct saturation level

- Non drip system